Researchers have produced the plastic alternative in much larger quantities than before. (Tanaka Tsutomu)

Researchers have produced the plastic alternative in much larger quantities than before. (Tanaka Tsutomu)

Plastic is an essential material in the modern world, but it's also environmentally costly to produce and a major pollutant.

A material called pyridinedicarboxylic acid, or PDCA, could help address at least some of those challenges following recent improvements to its manufacturing process.

Strictly speaking, PDCA is not an eco-friendly alternative to plastic, but rather a nitrogen-based, eco-friendly ingredient for making plastic that's more biodegradable. Previous research investigating the material's potential has emphasized its benefits as a suitable replacement for nonbiodegradable monomers of terephthalic acid in PET plastics.

Related: We Know Shockingly Little About Microplastic Impact on Fetuses

This new research, from a team at Kobe University in Japan, makes two key improvements to PDCA's production process, delivering the material at yields seven times greater than existing methods while cutting out the toxic waste that previously accompanied its manufacture.

"Our group approached the challenge from a new angle," says bioengineer Tanaka Tsutomu. "We aimed to harness cellular metabolism to assimilate nitrogen and build the compound from start to finish."

"The significance of our work lies in demonstrating that metabolic reactions can be used to incorporate nitrogen without producing unwanted byproducts, thereby enabling the clean and efficient synthesis of the target compound."

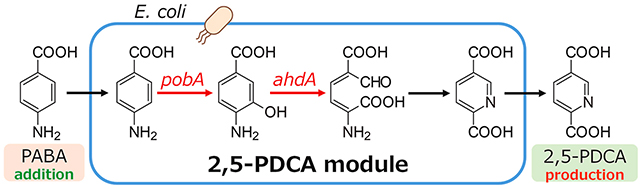

PDCA was produced using E. coli and enzymes. (Katano et al., Metab. Eng., 2025)

PDCA was produced using E. coli and enzymes. (Katano et al., Metab. Eng., 2025)The core part of the plastic production method involved feeding glucose to Escherichia coli bacteria that had been boosted with enzymes specially selected to convert an intermediate compound into the final material.

It wasn't a completely straightforward process, however. The revised production methods initially introduced a new toxic byproduct. The researchers found a solution in adding a separate chemical, pyruvate; however this step in itself may now introduce complications further down the line.

"Through refining the culture conditions, in particular by adding a compound that can scavenge H2O2, we could finally overcome the issue, although this addition may present new economic and logistical challenges for large-scale production," says Tanaka.

There's still plenty of work to do before this can be scaled up to a commercial level – in part due to the introduction of pyruvate – but the research demonstrates significant improvements in the creation of durable, biodegradable plastic.

Ultimately, PDCA is increasingly more viable as an alternative to petroleum-based products in plastic manufacturing. It can be produced using natural ingredients in a bioreactor system.

Another promising biomaterial announced this year is bacterial cellulose-hexagonal boron nitride, or BCBN for short. It makes use of bacterial cellulose fibers, which are carefully rotated to produce beneficial properties.

With plastic pollution piling up in our environment and in our bodies, biodegradable alternatives are a pressing goal for materials scientists.

"Our achievement in incorporating enzymes from nitrogen metabolism broadens the spectrum of molecules accessible through microbial synthesis, thus enhancing the potential of bio-manufacturing even further," says Tanaka.

The research has been published in Metabolic Engineering.

.jpg) 2 hours ago

3

2 hours ago

3

English (US)

English (US)