Rare earth elements are used in a wide variety of modern technologies, from wind turbines to phones. While the elements aren't all that rare, they are difficult to extract and purify.

A team led by researchers from Northeastern University in the US has developed a new way to pull REEs from waste left behind from coal mining, one that is up to three times more efficient than current approaches.

The waste, called coal tailings, consists of finely ground rock, water, and particles of coal, and we have vast amounts of the stuff accumulating in pits designed to keep it from contaminating the environment.

Related: How Feasible Is Asteroid Mining? A New Study Investigates

Most of this waste in the US is eventually used to bulk up building materials, or simply dumped. It's estimated that more than 600 kilotons of REEs could be extracted from every 1.5 billion tons of this landfill, something existing processes have struggled to manage efficiently.

This new extraction process involves two key steps: cooking the coal tailings in an alkali solution while being heated by microwaves, then using a nitric acid treatment to separate the REEs from the rest of the rock.

"The results show that alkaline pretreatment of coal tailings prior to acid digestion significantly influences REE extraction efficiency, with minimal extraction in the alkaline solution," write the researchers in their published paper.

Extracting REEs from coal tailings requires pulling them out of the clay minerals that tightly surround them. This is what has made previous extraction methods ineffective and led to scientists looking elsewhere for their REEs.

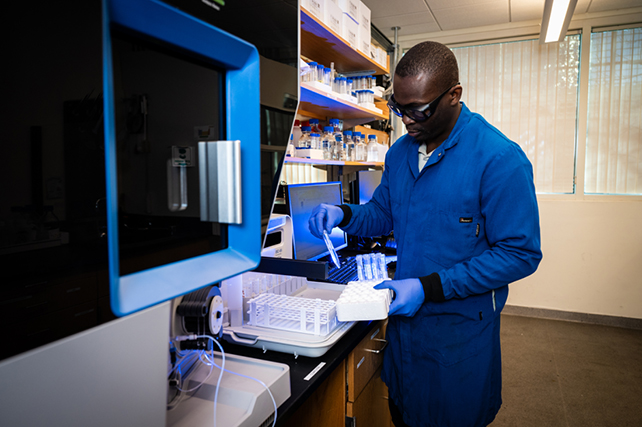

The extraction process used in the study may be difficult to scale up, say the researchers. (Alyssa Stone/Northeastern University)

The extraction process used in the study may be difficult to scale up, say the researchers. (Alyssa Stone/Northeastern University)The combined alkaline pretreatment and microwave heating changes the structure of the minerals encasing the elements, converting the coal tailings into a more porous form.

"It turns out that what you're doing is actually changing the solid structure of this material," says chemical biologist Damilola Daramola, from Northeastern University.

One of the REEs this process extracts is neodymium, an element that is used in high-strength magnets, electric cars, computer drives, and wind turbines – all crucial in our modern-day lives and our ongoing shift to greener technology.

This is all very promising so far, but multiple challenges remain. The extraction process may present a real improvement in terms of efficiency, but it remains expensive and might be difficult to scale up.

While there's an abundance of coal tailing waste to tap into – around 2 billion spare tons in the US state of Pennsylvania alone, for example, the mineral compositions of these rocks are going to vary depending on location. The extraction process would need to be refined in each case.

On top of that, there are plenty of other useful elements inside coal tailings, such as magnesium, that would ideally be extracted at the same time as REEs. That's another consideration that needs to be taken into account.

Related: Almost $100 Billion Worth of Rare Earth Elements May Be Buried in The US

All that said, a dramatic increase in extraction efficiency is something to be celebrated, even with caveats attached: the demand for REEs has never been greater, and we're going to need plenty more of them in the years ahead.

"This approach provides new insights into the mechanisms of REE release and the potential for optimizing alkali pretreatment of coal waste for efficient REE extraction," write the researchers.

The research has been published in Environmental Science & Technology.

.jpg) 1 hour ago

3

1 hour ago

3

English (US)

English (US)